Welding and Fabrication Solutions for the Utilities Sector

In the modern world, the Utilities Industry serves as the lifeblood of our society, providing essential services like electricity, natural gas, and...

3 min read

Cypress Fabrication Services

:

Jan 23, 2025 1:46:12 PM

Cypress Fabrication Services

:

Jan 23, 2025 1:46:12 PM

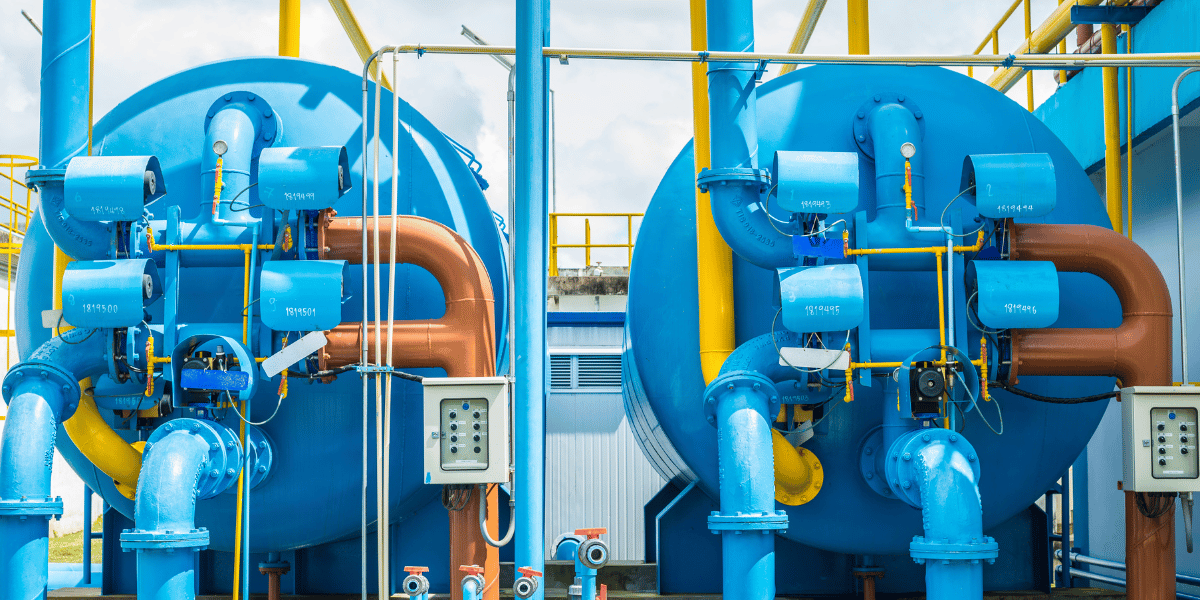

In the realm of modern water treatment, the need for robust, reliable infrastructure is paramount. Ensuring that critical equipment operates efficiently under demanding conditions requires a blend of precision, compliance, and durability. Custom fabrication services have emerged as an essential solution, enabling water treatment facilities to meet strict regulatory standards and deliver safe, clean water to communities and industries alike.

By partnering with an ASME certified company and leveraging advanced fabrication capabilities, the path to improved water treatment performance becomes clearer.

Water treatment fabrication calls for an unwavering commitment to quality. Every component—from storage tanks and water pump systems to filtration units—must withstand corrosive environments, varying pressures, and complex fluid dynamics. Expertly engineered parts, crafted within a state-of-the-art fabrication facility, support equipment longevity and reliability. When these critical elements are designed to precise specifications and fabricated with exacting standards, plant operators can trust their infrastructure to perform at peak efficiency for years to come.

Material selection, precision engineering, and alignment with rigorous safety criteria ensure that every fabrication project meets the evolving demands of the water treatment sector. By focusing on both performance and resilience, facilities can confidently handle current challenges while remaining adaptable to future expansions or regulatory changes.

Behind every high-quality water treatment project is a fabrication facility equipped with cutting-edge technology, skilled personnel, and a streamlined production process. Such an environment supports the seamless integration of components into existing or newly constructed treatment systems.

Advanced welding techniques, CNC machining, and sophisticated quality control checks help minimize errors and deliver components that fit flawlessly on-site. Efficient workflows also reduce project timelines, enhance cost-effectiveness, and provide greater certainty in meeting deadlines—ultimately boosting confidence among stakeholders and end-users.

In an industry where safety and compliance are non-negotiable, ASME certification stands as a hallmark of excellence. The American Society of Mechanical Engineers (ASME) certification signifies that a fabrication provider aligns with recognized codes and standards, ensuring equipment performance and reliability.

No two water treatment systems are identical. From municipal facilities tasked with delivering potable water to large-scale industrial operations requiring specialized filtration, customization is indispensable. Tailored fabrication services ensure that every element—be it a corrosion-resistant tank, an intricate piping network, or a highly specialized filtration unit—is engineered to meet site-specific demands.

This approach facilitates scalability and smooth integration with emerging technologies. Whether upgrading existing infrastructure or constructing an entirely new plant, custom fabrication provides the flexibility and precision required to navigate evolving regulations, fluctuating supply needs, and advancing environmental standards.

Investing in expertly fabricated components sets the stage for sustained success in the water treatment sector. High-quality fabrication translates into reduced maintenance needs, decreased downtime, and improved operational efficiency. Over time, facilities reap greater return on investment and the freedom to adapt as demands shift.

This future-proofing ensures that as communities grow, treatment standards become more stringent, or new technologies emerge, the foundational infrastructure can be readily modified and upgraded. Facilities built on such strong fabrication principles are better positioned to deliver reliable performance, no matter what challenges lie ahead.

As global water demands intensify and environmental considerations gain urgency, robust, future-focused fabrication solutions become indispensable. By selecting an ASME certified partner like Cypress Fabrication, water treatment operators can ensure that their infrastructure is not only engineered to withstand current pressures but also designed with adaptability in mind for the years ahead.

From precision-engineered components to tailored fabrication services, Cypress Fabrication brings together expertise, compliance, and innovation. By working with us, facilities can confidently overcome evolving challenges, maintain operational excellence, and ultimately secure the reliable, high-quality water treatment solutions that communities and industries depend on. At Cypress Fabrication, we're committed to helping you build a foundation for sustained success in water treatment—today, tomorrow, and beyond.

At Cypress Fabrication Services, we are a leading ASME-certified metal fabrication company with over twenty years of experience in the oil and gas industry. We specialize in custom metal fabrication for upstream, midstream, and downstream operations. All of our products are designed and fabricated to meet your specific process requirements, as well as various industry standards including our DNV skid certification, ABS certification, ASME pressure vessels, and AISC fabrication.

In the modern world, the Utilities Industry serves as the lifeblood of our society, providing essential services like electricity, natural gas, and...

In the rapidly evolving landscape of construction, the role of advanced fabrication methods has become increasingly crucial. At Cypress Fabrication,...

In the heartland of Louisiana, where the fertile soil stretches as far as the eye can see, the Agriculture Industry thrives, sustaining lives and...