The Power of Super Duplex Fabrication Pipe

In the ever-evolving realm of industrial infrastructure, one factor remains a constant challenge: the demand for robust and long-lasting piping...

4 min read

Cypress Fabrication Services

:

May 22, 2024 10:45:00 AM

Cypress Fabrication Services

:

May 22, 2024 10:45:00 AM

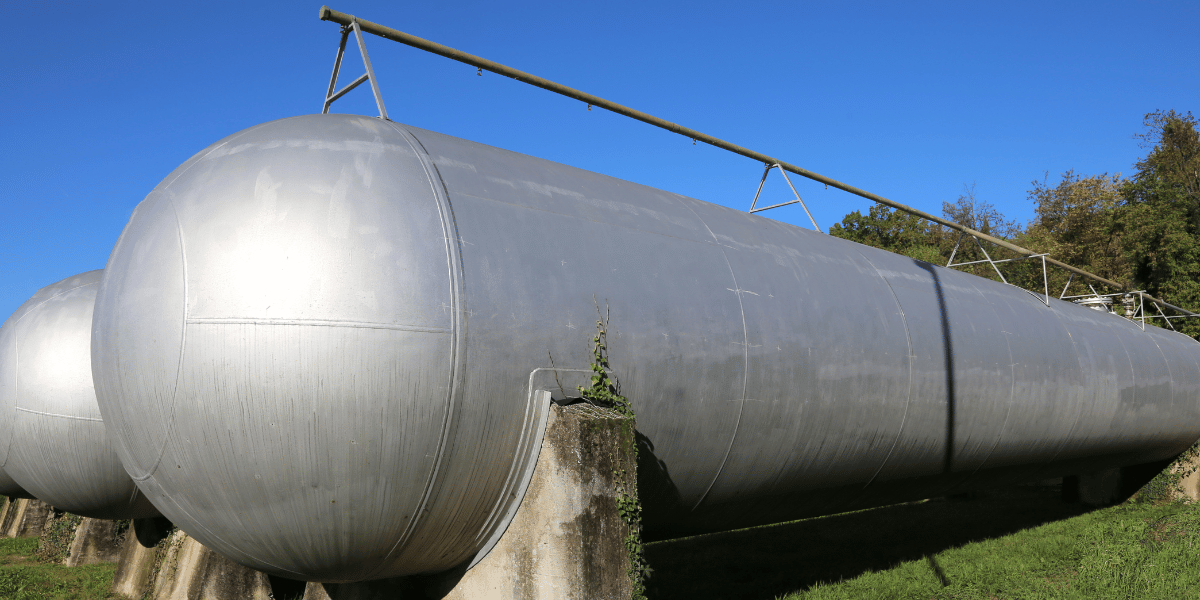

Pressure vessels are the backbone of many industries—chemical, petroleum, and power generation, to name a few. However, the constant demand for higher efficiency and long-term durability has led to engineers scratching their heads. How do you combine robustness with cost-effectiveness, especially under extreme environmental conditions? The answer lies in the evolution of ASME Vessel Fabrication materials, specifically, Stainless Steel and its even more potent cousin, Super Duplex.

The days when carbon steel and traditional stainless steel were the go-to materials for pressure vessel fabrication are gradually fading. Enter Duplex Stainless Steel, a hybrid material that combines the best features of austenitic and ferritic stainless steel phases.

This dual-phase material offers a unique balance, serving the mechanical strength of ferritic grades and the corrosion resistance of austenitic grades. When we talk about ASME Pressure Vessel Fabrication, it's essential to emphasize that Duplex Stainless Steel is making strides in setting new industry standards.

While Duplex Stainless Steel alone is a formidable material, Super Duplex takes it a notch higher. Characterized by higher concentrations of chromium, nickel, and molybdenum, Super Duplex offers even more exceptional strength and enhanced corrosion resistance. It exhibits extraordinary resilience against pitting and crevice corrosion, a property that is highly sought after in aggressive corrosive environments.

One of the most persuasive arguments for using Super Duplex Stainless Steel is its cost-effectiveness. The high initial material cost is often a point of contention, but when considering the total lifecycle of the vessel, Super Duplex emerges as a wise financial decision. With lower maintenance requirements and a longer lifespan, the material offers unparalleled cost savings in the long run.

When we zoom in on the world of ASME Vessel Fabrication, Duplex and Super Duplex Stainless Steels aren't just another option; they're a game-changing solution. These materials have revolutionized the way we think about pressure vessel durability, efficiency, and safety. Let's delve deeper into the myriad benefits they offer that are making industry veterans sit up and take notice.

One cannot overlook the importance of ASME standards when it comes to vessel fabrication. It offers a much-needed assurance of quality and safety. When combined with the high-performance characteristics of Super Duplex and Duplex stainless steel, you get a vessel that is not just robust but compliant with industry norms.

When discussing ASME Pressure Vessel Fabrication, one cannot sidestep the significance of ASME (American Society of Mechanical Engineers) standards. These guidelines are more than just a stamp of approval; they are the hallmark of quality, safety, and reliability. The ASME Boiler and Pressure Vessel Code (BPVC) lays out exhaustive criteria for the design, fabrication, inspection, and testing of pressure vessels. When a material like Duplex or Super Duplex Stainless Steel meets these stringent guidelines, the result is a pressure vessel that not only excels in performance but also in safety.

The marriage between ASME standards and Duplex Stainless Steel is more symbiotic than one might think. ASME standards often call for materials that can withstand extreme conditions, such as high pressure, corrosive environments, and fluctuating temperatures. Duplex and Super Duplex Stainless Steels answer this call with an astounding resilience against corrosive wear and mechanical failure. Therefore, fabricating pressure vessels using these materials often leads to a seamless compliance with ASME standards without compromising the vessel's integrity or performance.

ASME's progressive outlook on technological advancements has opened the doors for incorporating cutting-edge materials like Duplex and Super Duplex Stainless Steels. With evolving welding techniques and improved quality control measures, it has become increasingly feasible to employ these materials in complex pressure vessel designs that still adhere to ASME standards. These advancements not only drive innovation but also set new benchmarks for what can be achieved in pressure vessel fabrication.

Lastly, safety is a paramount concern in any industry utilizing pressure vessels. ASME standards serve as a robust framework for ensuring that safety isn’t compromised at any stage of the vessel's lifecycle. The extraordinary mechanical properties of Duplex and Super Duplex Stainless Steels provide an additional layer of assurance. Their high tensile strength and exceptional resistance to stress corrosion cracking contribute to a safer operational environment, aligning perfectly with the safety principles endorsed by ASME standards.

In conclusion, the integration of Duplex and Super Duplex Stainless Steels with ASME standards results in a pressure vessel that embodies the pinnacle of modern engineering—a harmonious blend of high performance, safety, and long-lasting reliability.

When it comes to marrying top-notch quality with enduring resilience, Cypress Fabrication has been a market leader. Specializing in ASME Vessel Fabrication, we offer a range of pressure vessels designed to meet the rigorous demands of your industry.

Our extensive experience with Stainless Steel and Super Duplex ensures that you’re not just investing in a vessel but a long-term solution for your operational challenges. Here at Cypress Fabrication, we don't just meet standards; we exceed them.

At Cypress Fabrication Services, we are a leading ASME-certified metal fabrication company with over twenty years of experience in the oil and gas industry. We specialize in custom metal fabrication for upstream, midstream, and downstream operations. All of our products are designed and fabricated to meet your specific process requirements, as well as various industry standards including our DNV skid certification, ABS certification, ASME pressure vessels, and AISC fabrication.

In the ever-evolving realm of industrial infrastructure, one factor remains a constant challenge: the demand for robust and long-lasting piping...

In the intricate world of metalwork, stainless steel stands out as both a challenge and a reward. At Cypress Fabrication, we dive deep into the art...

When it comes to high-pressure storage or processing of liquids or gases, manufacturers rely on pressure vessels. These closed containers find...