Metal Fabrication in the Food and Beverage Industry

In the bustling world of food and beverage production, precision and quality reign supreme. Metal fabrication stands as a silent yet indispensable...

Metal fabrication is a process that encompasses the entire production of metal components from raw materials to finished goods. It's versatile, complex and has been around for centuries. Whether you're looking for precision parts or specialized structures, metal fabrication offers a cost-effective way to create them. But what does it really mean? In this blog post, we will discuss the various types of processes involved in metal fabrication and what industries utilize it.

Metal fabrication typically begins with a design that must be turned into a tangible part or product. The design will often require specialized tools for accurate measurements and cuts during the production process. Techniques such as machining, shearing, punching, and forming are often used to convert raw materials into the desired shape.

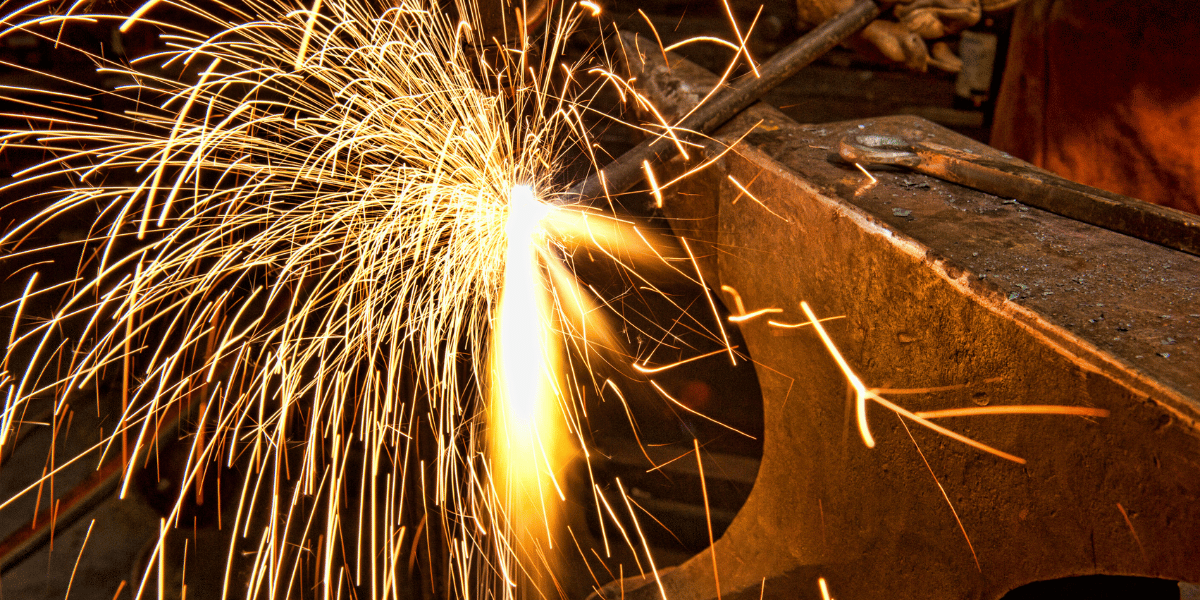

After all individual parts have been cut and formed they are then welded together using either arc welding or MIG welding. From there it is a matter of grinding, sanding, and polishing the finished product to achieve the desired appearance and functional requirements.

Overall, metal fabrication is an important part of manufacturing processes across many industries and can be used to create anything from automobiles to artwork. The process requires skilled craftsmanship as well as specialized tools and equipment to accurately create components according to design specifications. With proper planning and execution, metal fabrication can produce high-quality parts that meet customer needs.

Metal fabrication involves more than just shaping metal. Even simple products may require multiple techniques and processing steps. The variety of techniques used in fabrication ensures that any desired shape or form can be achieved with a combination of tools and processes. For this reason, metal fabrication is a highly versatile and cost-effective process for creating parts and products. Common techniques and processes include:

Cutting includes both manual and automated processes used to shape metal. These include drilling, punching, sawing, laser cutting, plasma cutting, and waterjet cutting.

Metal can be bent using a press brake which is a machine that uses pressure and heat to form metal into the desired shape.

Computer Numerical Control (CNC) machining is a process in which computer-controlled machines are used to cut metal into precise shapes. This method allows for the creation of complex parts that would otherwise be too difficult to produce manually.

Welding involves fusing two or more pieces of metal together by melting them at their edges. The most common types of welding are arc welding (MIG/TIG) and oxyacetylene welding (OAW).

The finishing process polishes the surface of a part or product for aesthetic purposes as well as protection from corrosion. Finishing techniques include sandblasting, grinding, powder coating, and anodizing.

Metal fabrication has become an integral part of many industries, allowing for the production of complex parts with precise measurements and accurate finishes. With its stylish designs and strong materials, metal fabrication is a cost-effective way to create quality products that meet customer needs.

Metal fabrication is used in various industries such as:

As technology advances, so does the use of metal fabrication processes in each industry. Automation tools such as CNC machining and welding robots are becoming more common in factories, allowing for faster and more precise results than ever before.

Similarly, 3D modeling, simulation, and printing has gained traction as another tool used in metal fabrication applications. 3D modeling and simulation allow a designer to digitize a design concept, articulate it into a three-dimensional object and simulate potential changes before production begins. Meanwhile, 3D printing allows manufacturers to rapidly produce custom designed components directly from digital models with speed and accuracy. With the use of advanced technologies, metal fabrication can continue to provide quality products and services for years to come.

Overall, metal fabrication is a critical process used in many industries to create parts and products. It requires highly skilled craftsmanship as well as specialized tools and equipment to accurately shape metal into desired forms with precise measurements and functional requirements. With its versatile techniques, cost-effectiveness, and technological advances, it has become an important part of manufacturing processes around the world.

With Cypress Fabrication's experience, expertise, and unwavering customer service, you can ensure that your next project meets the highest industry standards and regulations. Our team is committed to building strong, trusting relationships with our customers and partners. We believe that working collaboratively is essential for a successful project from initial design to construction and final evaluation.

If you're in need of fabrication and construction services, let's talk more about your project! Connect with us more by clicking below.

At Cypress Fabrication Services, we are a leading ASME-certified metal fabrication company with over twenty years of experience in the oil and gas industry. We specialize in custom metal fabrication for upstream, midstream, and downstream operations. All of our products are designed and fabricated to meet your specific process requirements, as well as various industry standards including our DNV skid certification, ABS certification, ASME pressure vessels, and AISC fabrication.

In the bustling world of food and beverage production, precision and quality reign supreme. Metal fabrication stands as a silent yet indispensable...

Marsh buggies are essential vehicles used by many industries such as oil and gas, mining, construction, forestry, and agriculture. These specialized...

In the industrial heartland of Lafayette, Louisiana, where precision meets passion, Cypress Fabrication proudly stands as a beacon of excellence in...