Elevating Water Treatment with Custom Fabrication Services

In the realm of modern water treatment, the need for robust, reliable infrastructure is paramount. Ensuring that critical equipment operates...

4 min read

Cypress Fabrication Services

:

Feb 16, 2023 1:00:00 PM

Cypress Fabrication Services

:

Feb 16, 2023 1:00:00 PM

Oil and gas companies are increasingly turning to fabricate water filtration and treatment equipment for their operations. This can have a large impact on reducing the environmental footprint of oil and gas operations, maximize efficiency, as well as improving quality control over the production process. In this article, we’ll explore the importance of and the different solutions for fabricating water filtration and treatment equipment for oil and gas.

Oil and gas extraction from sedimentary rocks like limestone or sandstone can be a tricky business, as these formations are highly porous. This means that drilling for these resources will also result in the production of water from the reservoir itself. That's when water treatment methods come into play - separating oil, gas, and water is essential to ensure all components of this mixture can be used properly downstream.

In the oil production industry, injecting water or steam into wells can significantly boost the recovery rate of oil. This process is termed a 'waterflood' when water injection is utilized and a 'steam flood' if it's done with steam. When properly implemented, both these methods will maintain pressure in reservoirs while improving overall output vs what was achieved through primary extraction techniques. The viscosity of extracted oil also reduces due to steaming injections thus leading to even higher yields.

Without proper water treatment, oil companies will be creating a lasting environmental hazard with the waters they use and then release into the sea or neighboring rivers. Thus, it is critical to ensure that all oil manufacturers have adequate water treatment facilities in place before any discharge can occur.

The most common course of action for oil and gas operations is to deploy a combination of remediation and dewatering solutions. Remediation technologies are employed to purify water from any contaminants that may have been brought up during extraction, while the latter focuses on removing excess moisture from the mixture before it can be sent back into reservoirs.

Two of the most popular approaches used for remediation are pumping and oil and water separation. In this method, a centrifugal pump is used to draw the oil-water mixture from the well and then divert it into two separate vessels. In order to handle high pressures, charge pumps ensure that centrifugal and positive displacement pumps maintain consistent pressure and prevent cavitation, enabling optimal performance throughout the fluid handling process.The oil vessel will contain just the crude while the second will be holding a mixture of water and other solids or sediments that have been entrained during extraction.

For complex remediation scenarios that call for pumping, specialized systems are key. Dewatering aeration pumps, equipped with high-quality gaskets, blend pumping and biological treatment to securely remove toxic liquids from construction sites or any other areas in need of water remediation solutions (see pumps for chemical dosing and water disinfection). In short, these state-of-the-art tools offer a safe and reliable way to address environmental pollution issues quickly and efficiently.

Portable dewatering aeration systems are most commonly used for short-term onsite applications, yet they also have the capability to offer long-term solutions when integrated with current wastewater treatment facilities. The trailer-mounted design of these systems makes them ideal for a variety of operations and settings.

Portable and efficient oil and water separators are the perfect solution to effectively perform the job. Crafted with cutting-edge technology, these enhanced systems can easily remove both free-floating and submerged non-emulsified oils as well as other solid materials that dissolve in oil. The devices rely on gravity for separation since oil is denser than water, which ensures a successful extraction process.

These systems are extraordinarily rugged and reliable, providing dependable results in extreme conditions that range from vehicle washing to groundwater treatment. Plus, their portability makes them both simple to use and easy to incorporate into existing systems. With these separators designed for oil and water applications on hand, you can confidently handle aircraft fueling jobs as well as bulk petroleum storage projects or contaminated site remediation tasks with the utmost efficiency.

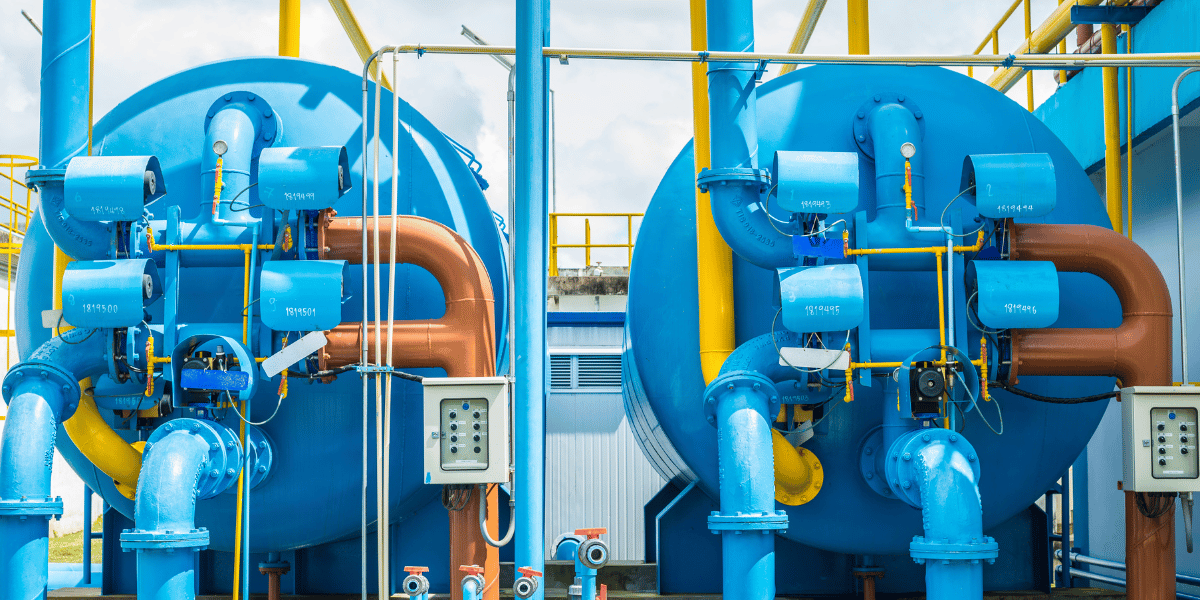

Cypress Fabrication's skills and advanced infrastructure allow us to engineer, fabricate, and install large water treatment projects. Our enormous scope of piping fabrication and manufacturing services gives us the advantage of creating sophisticated solutions that are tailored precisely to our customer's needs.

At Cypress Fabrication, our committed and creative design and fabrication processes ensure that all of our customers receive the best quality equipment to fulfill their needs. With performance-driven designs and cost optimization in focus, we produce machines with maximum efficiency for superior outcomes.

Types of custom water treatment equipment we've fabricated include:

At Cypress Fabrication, we craft our design and fabrication processes deliberately to generate the most exceptional quality products and solutions for any wastewater treatment. As part of the engineering process, our engineers are committed to collaborating with your team in order to conceive equipment that complies with all your facility’s specifications. We meticulously select components that have an optimal configuration as well as system designs that will ultimately meet or exceed your goals.

With decades of experience in design and fabrication, our team of machinists and welders are amongst the most competent professionals in the industry. We guarantee that all components such as control panels, electrical systems, piping systems, framing, and structures will be hand-welded to ensure optimal quality with extraordinary durability. Our services not only provide a lasting system but also an enhanced performance throughout its lifespan.

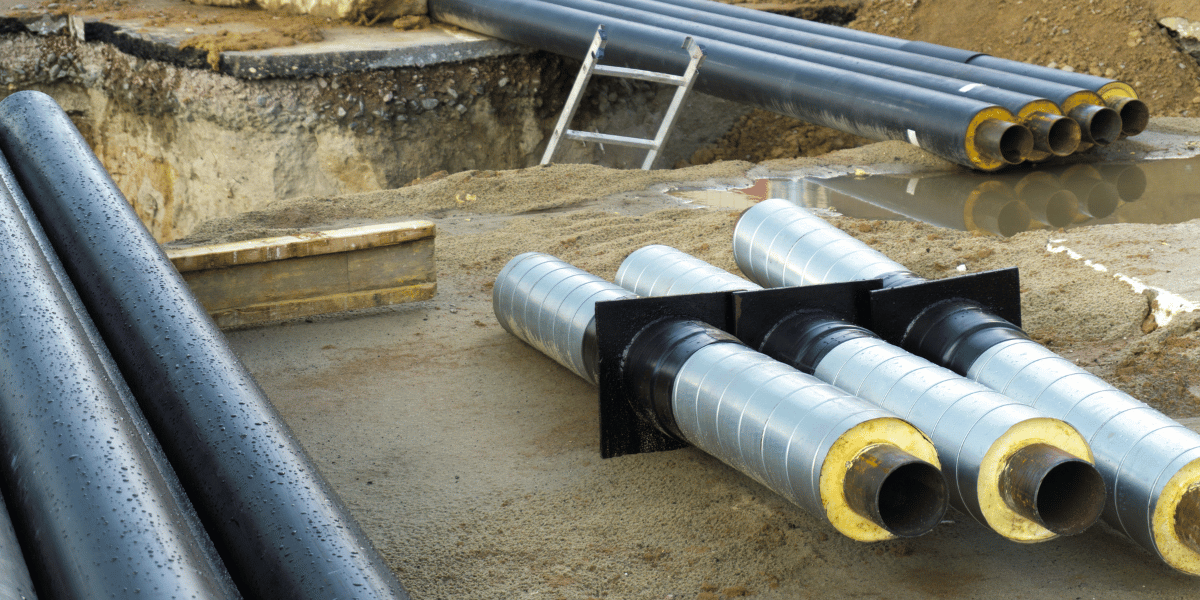

In all wastewater treatment systems, it's important to have knowledge and access to various metals for more durable equipment, such as super duplex pipes.

Super duplex pipes combine the features of ferritic steel and austenitic steel, giving them high strength and high corrosion resistance, plus the ability to resist stress corrosion cracking. With remarkable durability and affordability, these corrosion-resistant metals stand out among their counterparts that have higher levels of costly alloying elements. Not only are they widely available, but they also offer a competitive price point.

Other more durable exotic metals include:

At Cypress Fabrication, we have depths of experience fabricating water filtration and treatment equipment for our clients in the oil and gas industry.

We work with all types of companies in the oil and gas industry and can help you with projects big and small. If you’re looking for someone to partner with on your next project, give us a call. We’d be happy to provide you with a quote for our fabrication services.

At Cypress Fabrication Services, we are a leading ASME-certified metal fabrication company with over twenty years of experience in the oil and gas industry. We specialize in custom metal fabrication for upstream, midstream, and downstream operations. All of our products are designed and fabricated to meet your specific process requirements, as well as various industry standards including our DNV skid certification, ABS certification, ASME pressure vessels, and AISC fabrication.

In the realm of modern water treatment, the need for robust, reliable infrastructure is paramount. Ensuring that critical equipment operates...

In today’s rapidly evolving energy and telecommunications landscape, the utilities industry stands at the forefront of delivering reliable,...

Food and beverage manufacturers face heightened pressure to ensure the quality and affordability of their products. Consequently, they need to...